As the leading producer and supplier of cow milking machines, Mahesh Engineering Works offers creative and dependable dairy farming solutions. Our milking machines, which are highly regarded for their exceptional quality and effectiveness, are engineered to maximize output while safeguarding the welfare of dairy cows. Mahesh Engineering Works is dedicated to providing dairy farmers with high-quality, user-friendly equipment that meets their various needs. They make a strong use of cutting-edge technology and prioritize client happiness. We are at the forefront of the business thanks to our knowledge and commitment, which assist farmers in streamlining their processes and achieving the highest possible milk yield.

- Sector Heading: acknowledged as the leading provider and manufacturer of cow milking machines. Vast knowledge and a strong track record in providing dairy equipment of the highest caliber.

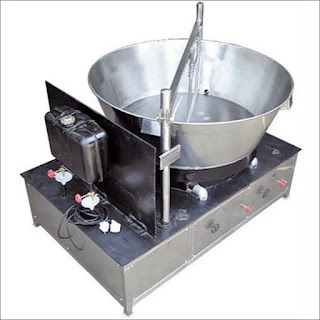

- Product Caliber: milking machine made with cutting edge technology that is dependable, long-lasting, and effective. Make sure that the milking procedures used to ensure the health and welfare of dairy cows are efficient and kind.

- Client Contentment: Dedicated to providing excellent customer service, offering full assistance from the point of sale to installation and upkeep. High client satisfaction levels as a result of the goods and services' dependability and quality.

- Product Selection: Numerous cow milking machines that are suitable for dairy farming at various levels, from small family farms to massive commercial enterprises.Devices made to boost productivity, cut labor expenses, and produce more milk.

- Worldwide Reach: utilizing a strong distribution network to cater to a wide range of customers both domestically and abroad. Supplying top-notch milking equipment that adhere to international norms and laws to a number of nations.

- Post-purchase Assistance: complete after-sale support, which includes technical support, spare part availability, and maintenance services. Resources and training courses to assist farmers and operators in properly operating and maintaining their milking equipment.

- Economic Repercussions: contribution to the agricultural economy through the provision of instruments that raise the dairy industry's productivity and profitability.Assistance to the neighbourhood through the creation of jobs and the use of sustainable farming methods.

To sum up, Mahesh Engineering Works is the industry leader in the production and delivery of cow milking machines, and it represents perfection in this regard. Our products are made with an unwavering dedication to quality, innovation, and customer satisfaction. They are made to maximize dairy operations while maintaining animal welfare and production. With our extensive selection of dependable and effective milking systems and our strong after-sales service, dairy producers can confidently accomplish their operational objectives. Leading the way in the industry, Mahesh Engineering Works is advancing sustainable dairy farming methods and boosting the world's agricultural economy.